Capabilities and Services Includes:

Work requests can be submitted by filling the Optics Group's work request from. Please make the crystal optics requests in the category of "Fabrication of Crystal Optics/Chemical Etching". The crystal optics facilities are described below. | ||

| Dicing/Cutting Laboratory (COF2) | ||

The lab is equipped with: (1) Two dicing saws for precisely and delicately cutting relatively thin wafers and plates into distinct pieces; (2) Two diamond-wire saws for cutting/slicing crystal boules of Si and Ge up to 8 inches in diameter and length. The diamond-wire saw cuts crystals gently with low strains/damages and minimal loss of valuable material; (3) A fast Blanchard surface grinder.

| ||

| Optics Machining Shop (COF4) | ||

This lab is equipped with (1) two high-precision surface grinders, (2) a rotary diamond blade saw for cutting large crystal boules, (3) a hole drilling machine, (4) lapping machines, and many other machining equipment. | ||

| Etching Laboratory (Bldg. 401/L0104) | ||

This facility is used to etch crystals using wet chemical methods (mainly HF and HNO3) to remove surface layers that have stresses/strains/damages induced by machining processes.

| ||

| Polishing Lab (COF3) | ||

| The Polishing Laboratory utilizes the following lappers/polishers (in addition to various small polishers and lappers): | ||

| Hyprez LM28 Lapping Machine (Engis) | ||

| ||

| Strasbaugh 6DF-1 Precision Polishmaster Qty 2 | ||

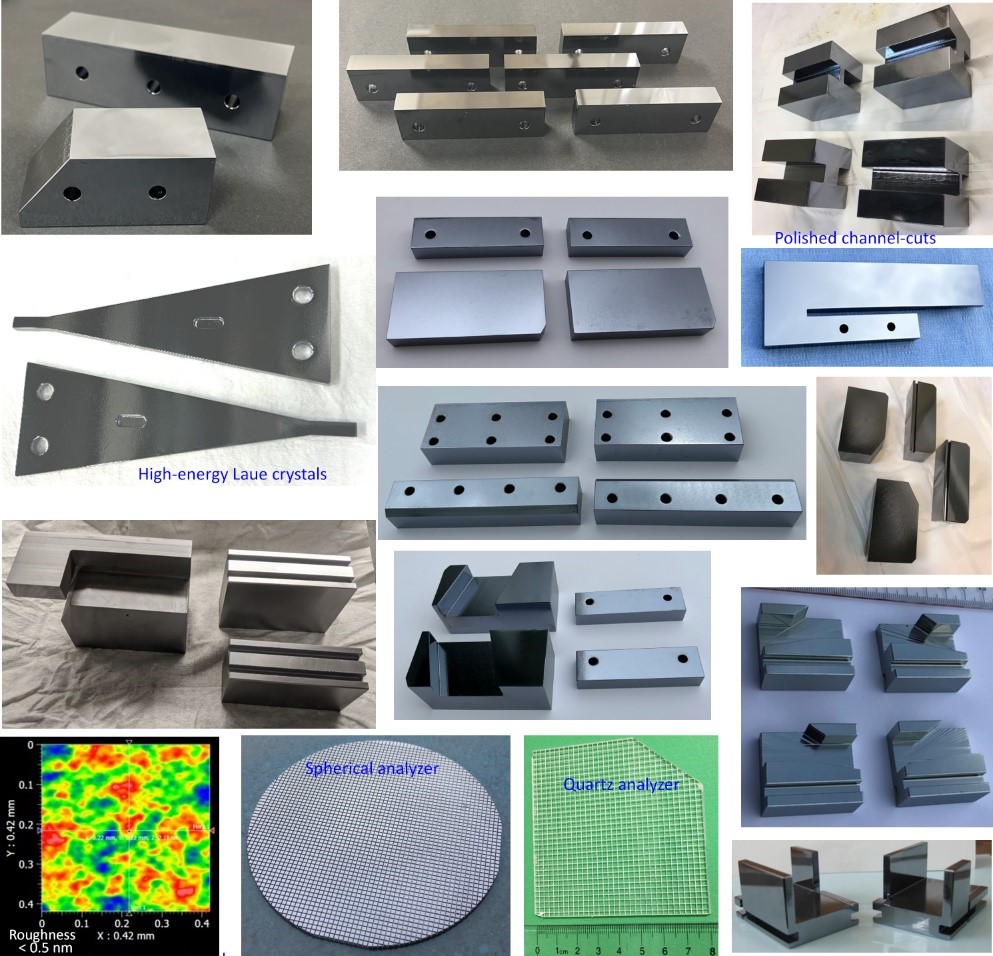

This versatile overarm polisher can be outfitted with various plates and pads to perform intermediate and fine polishing steps using diamond or colloidal silica slurries. • A novel homemade automated machine for polishing channel-cut crystals, Channel-Cut High Resolution Polisher (C-CHiRP). This new homemade instrument can be used for machine-polishing channel-cut crystal surfaces or other special-shaped crystal surfaces that do not have top flat surfaces (so that normal polishers cannot polish them). It can achieve strain-free channel-cut walls with roughness also toward 1Å. | ||

| Inspection Equipment | ||

| The Fabrication Laboratory is equipped with a DIC microscope for immediate inspection during the polishing process. Optics requiring more detailed inspection and accurate measurements are sent to the Metorology Laboratory. | ||

| X-ray Laboratory (Bldg. 401/L0111 and 401/L0120) | ||

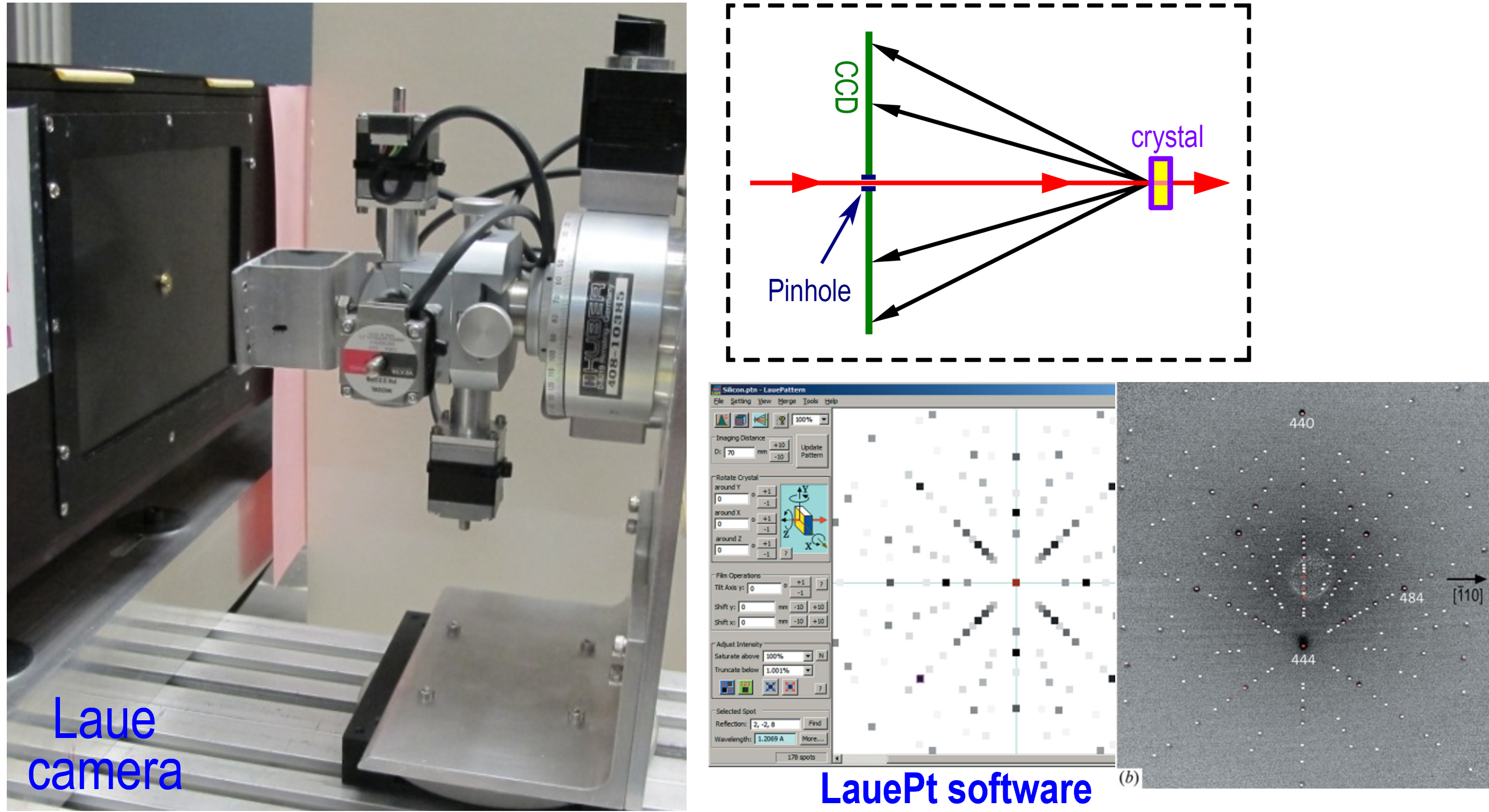

This laboratory is equipped with three main instruments:

Advanced X-ray characterization of crystal optics is carried out at the 1-BM Optics and Detectors Test Beamline. | ||

| Crystal Optics Research and Development | ||

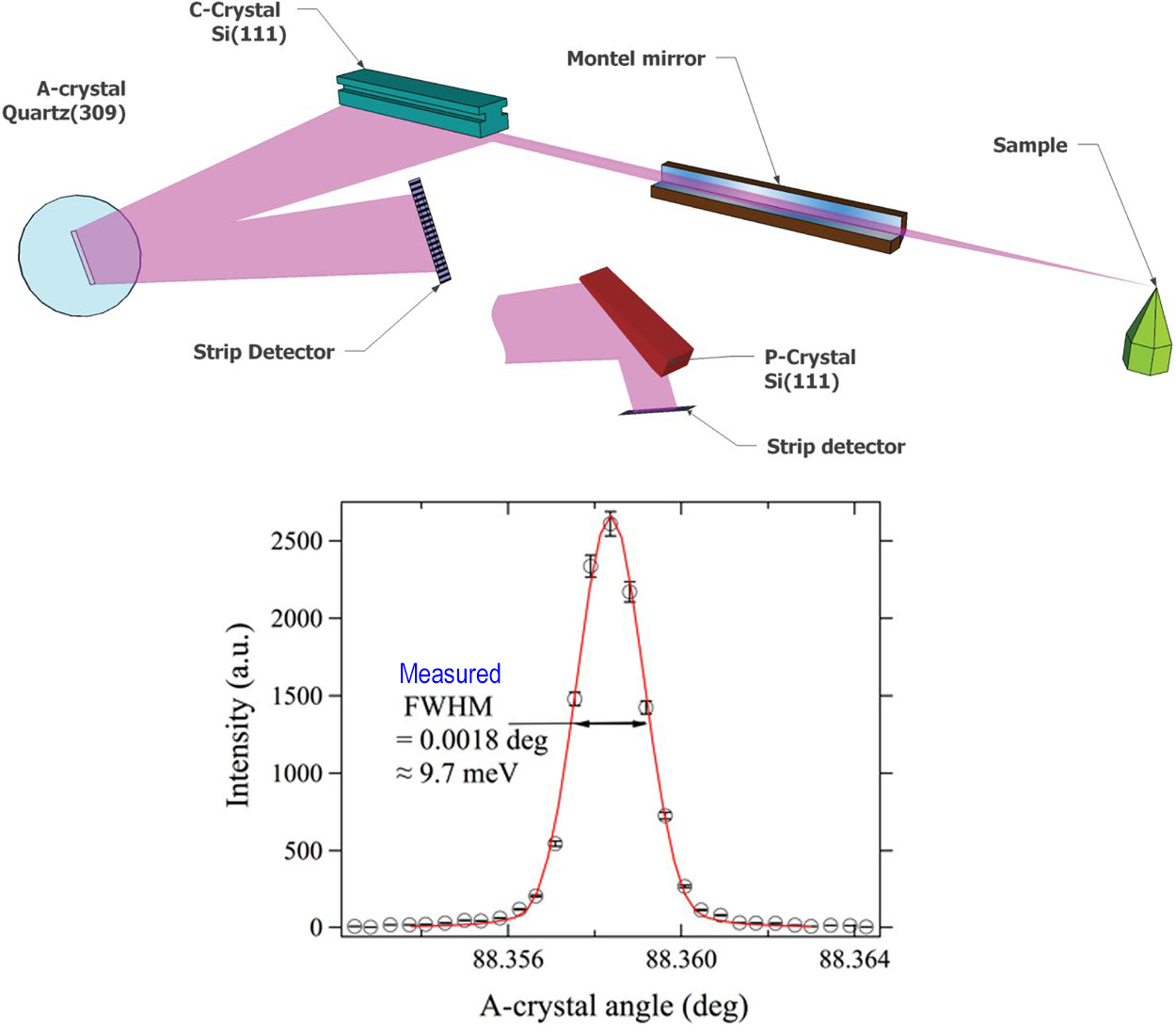

R&D in crystal optics is carried out either independently, or jointly with the APS beamline scientists and user community, or in collaboration with other facilities to keep the group at the state-of-the art in x-ray optics. Examples include designing and development of high-to ultrahigh- resolution crystal monochromators and analyzers (from sub-10 meV to sub-meV) for IXS/RIXS, strain-free crystal polishing with roughness toward 1A, automated machine polishing of channel-cut crystals, quartz-based X-ray optics, diamond optics, SiC optics, etc.

|

| Development of novel sub-10-meV RIXS system with a flat quartz analyzer (in collaboration with IXN Group, Kim et al., Scientific Reports 8, 1598 (2018). |