Strong, lightweight aluminum-copper alloys have been used in aircraft and automotive designs for decades, but little is known about their structural mechanisms during deformation. Recent Arizona State University (ASU) materials science doctoral graduate Shashank Kaira set out to find answers. His research, carried out at the U.S. Department of Energy’s Advanced Photon Source (APS) and published in the journal Acta Materialia, earned a competitive Acta Student Award for the impact of its results.

Strong, lightweight aluminum-copper alloys have been used in aircraft and automotive designs for decades, but little is known about their structural mechanisms during deformation. Recent Arizona State University (ASU) materials science doctoral graduate Shashank Kaira set out to find answers. His research, carried out at the U.S. Department of Energy’s Advanced Photon Source (APS) and published in the journal Acta Materialia, earned a competitive Acta Student Award for the impact of its results.

The Acta Student Award is given to first-author graduate students who have papers published in one of the four Acta journals. Publishing in the materials science journal Acta Materialia is highly competitive — only a handful of papers reporting on research judged to be making major contributions to the field are selected for the international student award.

“I am extremely honored to be the recipient of this prestigious award and really grateful to receive such recognition for our work published in Acta Materialia, one of the most revered peer-reviewed journals in the field of materials science,” Kaira said. “I’m hopeful I can continue to innovate and effectively contribute to the emerging field of materials science.”

He collaborated with Nikhilesh Chawla, Fulton Professor of materials science in the Ira A. Fulton Schools of Engineering at ASU, as well as other ASU materials science graduate and undergraduate students. The ASU team also worked with researchers and in the APS facilities at the Argonne National Laboratory to explore the microstructural evolution and deformation behavior of aluminum-copper alloys.

Kaira and the research team took a different approach from traditional characterization methods, which can be destructive to the alloys and restrict the insights the characterizations are able to provide. The team instead using 3-D x-ray imaging to view deformation over time to better understand what happens.

“By using this state-of-the-art technique, we were able to see things that were happening with respect to how the structure deforms in a way that provides all kinds of new insights and new mechanisms that we haven’t been able to see before,” Chawla said. “Shashank was able to answer questions that have been unanswered for the last 50 years or so.”

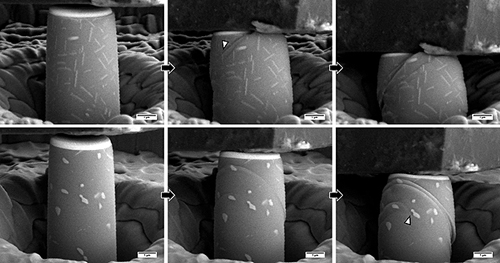

The advanced characterization techniques Kaira and the research team used allowed them to better understand the nanoscale processes occurring in aluminum-copper alloys. They looked at the complex 3-D dispersions of brittle intermetallic precipitate particles that strengthen the alloy (Fig. 1) — think of the crunchy chocolate flakes in soft mint ice cream. When immense pressure is put on the alloy, these particles deform and change the properties, strength and behavior of the metal.

The advanced characterization techniques Kaira and the research team used allowed them to better understand the nanoscale processes occurring in aluminum-copper alloys. They looked at the complex 3-D dispersions of brittle intermetallic precipitate particles that strengthen the alloy (Fig. 1) — think of the crunchy chocolate flakes in soft mint ice cream. When immense pressure is put on the alloy, these particles deform and change the properties, strength and behavior of the metal.

“Understanding such phenomena in metallic systems can be key to nano-engineering their microstructure and aid in designing next-generation structural materials with enhanced mechanical properties,” Kaira said.

This research was conducted at both the ASU Tempe campus in Chawla’s Center for 4D Material Science and at the X-ray Science Division 32-ID-C x-ray beamline at the APS (an Office of Science user facility at Argonne). The work at the XSD Imaging Group’s beamline 32-ID-C was carried out in collaboration with XSD beamline scientists Vincent De Andrade and Francesco de Carlo

Researchers in Chawla’s Center for 4D Material Science use x-ray tomography and other techniques to study the microstructures of materials as a function of time — the fourth dimension — and its effect on 2-D (flat) and 3-D (cubicle and spherical) objects.

To work at the APS, Kaira needed a solid proposal for how he was going to use the facilities, and a precise plan for his experiments during the few days every six to nine months he had access to the lab's equipment.

“There are a lot of hoops to jump through and there is a lot of preparation that has to be done prior to going on the trip. Then it’s a lot of pressure because you have three days to get everything done,” Chawla said. “Shashank was really good at doing all of that and navigating through all of the challenges just to do the experiments, then coming back with terabytes of data and analyzing it.”

Kaira says he is thankful for the help he received from Chawla, his ASU research team members and his Argonne collaborators, as well as the research results the collaboration made possible.

With the aid of the facilities and tools available at Argonne, Kaira was able to make observations that answer fundamental questions about the role of precipitative particle deformation and gain new knowledge that can be used to develop better and more sophisticated aluminum alloys for the aircraft and automotive industries. The Acta journal editors recognized these important contributions with the Acta Student Award.

“Shashank was one of my best students in the last 20 years here at ASU,” Chawla said. “I know he worked really hard for this. I’m not surprised, but it’s pretty amazing that he got this award.”

Kaira is now a failure analysis research and development engineer for Intel. His doctoral research into understanding microscale phenomena in different materials using advanced characterization techniques has been useful in his current work.

“A significant part of my doctoral research involved fundamentally understanding a multitude of microscale phenomena in different materials using advanced characterization techniques,” Kaira said. “A thorough understanding of such complex material and device interactions can play a crucial role in enabling the development of robust next-generation semiconductor devices and microelectronic packaging technologies.”

See: C. Shashank Kaira1, Christopher Kantzos1, Jason J. Williams1, Vincent De Andrade2, Francesco De Carlo2, Nikhilesh Chawla1, *, “Microstructural evolution and deformation behavior of Al-Cu alloys: A Transmission X-ray Microscopy (TXM) and micropillar compression study,” Acta Mater. 144, 419 (2018). DOI: 10.1016/j.actamat.2017.11.009

Author affiliations: 1Arizona State University, 2Argonne National Laboratory

Correspondence: * [email protected]

The authors are thankful for financial support from the Army Research Office (ARO) under Contract No. W911NF1410550 (Dr. Michael Bakas and Dr. David Stepp, Program Managers). We also acknowledge the use of facilities within the Center for 4DMS and the Leroy Eyring Center for Solid State Science at Arizona State University. This research used resources of the Advanced Photon Source, a U.S. DOE Office of Science User Facility operated for the DOE Office of Science by Argonne National Laboratory under contract no. DE-AC02-06CH11357.

Argonne National Laboratory seeks solutions to pressing national problems in science and technology. The nation's first national laboratory, Argonne conducts leading-edge basic and applied scientific research in virtually every scientific discipline. Argonne researchers work closely with researchers from hundreds of companies, universities, and federal, state and municipal agencies to help them solve their specific problems, advance America's scientific leadership and prepare the nation for a better future. With employees from more than 60 nations, Argonne is managed by UChicago Argonne, LLC, for the U.S. DOE Office of Science.

The U.S. Department of Energy's Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, visit the Office of Science website.