Each smartphone picture we take and each online form we fill out increases the need for efficient and inexpensive computer storage. One new possibility for improving existing memory hardware is to incorporate a ferroelectric material into random-access memory (RAM), removing the need for a continuous power supply and allowing for faster changes to memory cell values.

To incorporate a ferroelectric material into RAM, scientists must first characterize the material's ability to act like a memory cell. Previously published investigations into bismuth ferrite, a lead-free multiferroic material, haven't completely assessed this type of behavior nor taken full advantage of bismuth ferrite's sensitivity to light. Recent research by an international team demonstrates a technique for characterizing the response of bismuth ferrite to light and shows how photodoping (applying light to the material) forms small, transient domains, making bismuth ferrite an excellent candidate for ferroelectric applications.

Ferroelectric materials are well-suited for electronics because of their naturally occurring ferroelectric domains which carry spontaneous electric polarization. These domains can be manipulated by externally applied forces, such as electric fields, changes in surface chemistry, physical strain of the material, or in this case, light. This manipulation is similar to the way values stored in computer memory are deliberately changed and so understanding the response of these materials to external forces gives insight into the material's prospects for use in memory cell circuits. The material's aptitude depends on a few characteristics: how the material's domains respond at short intervals following the application of the external force, that individual domains can be identified, and that the presence of domains can be reversed.

To characterize any domains formed within the bismuth ferrite by photodoping, the team needed to modify existing investigative methods. While pump-probe X-ray diffraction techniques allow for measurements of domain responses on the timescales of interest (picosecond to nanosecond), this technique results in domain characteristics which are averages of multiple domains. To achieve sufficiently high spatial resolution, the team used nanoprobe X-ray diffraction imaging in combination with pump-probe techniques to resolve individual domains on the timescales of interest.

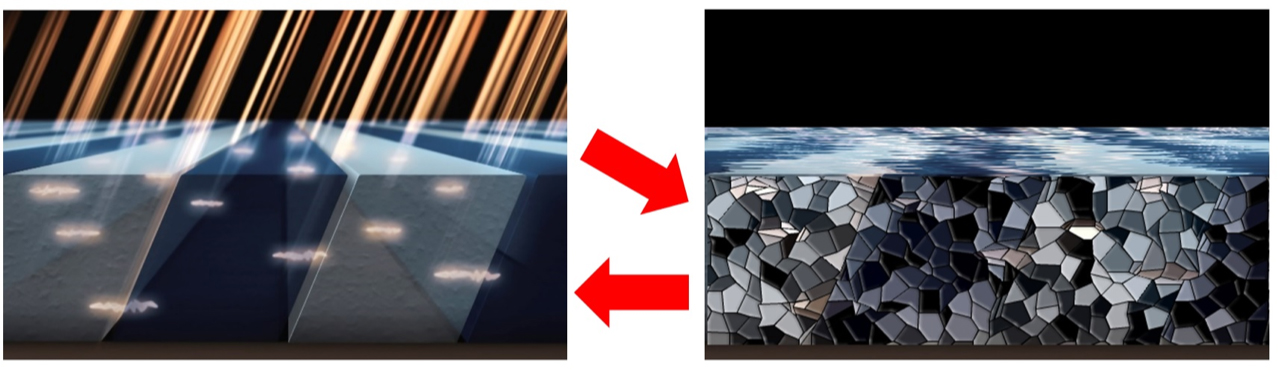

Before beginning photodoping, the team imaged thin sections of bismuth ferrite for a baseline. The team confirmed the ferroelectric domains in bismuth ferrite appear as stripes. These stripes occur because of the mechanical interaction between the bismuth ferrite thin film and the underlying substrate, as well as the rhombohedral form of the bismuth ferrite crystal.

Using beamline 26-ID-C, the team took nanoprobe X-ray diffraction imaging as a function of light intensity values (fluence) and at multiple time intervals after photodoping. Initial results showed that the stripe pattern disappeared under application of the higher light intensity. The team hypothesized that smaller, island-like domains were forming in place of the stripes. To better understand the stripes' disappearance, the team looked at a one-dimensional cross-section of the material as a function of time after photodoping. Here they found that the striped domains disappeared but began to return after a short period, yielding information about the life spans of domains. This also showed that the bismuth ferrite produces transient, or time-limited, domains when reacting to photodoping.

To test their hypotheses about whether new, smaller domains form, the team performed time-domain diffuse scattering measurements using beamline 7-ID-C to look at domain size and the domain walls. They found that the initial stripes split into smaller domains through the creation of new domain walls. These new domains were even smaller than the resolution of the team's instruments.

The team hypothesized that the presence of additional charge-carrying particles, introduced by the photodoping event, might explain the creation of charged domain walls within the bismuth ferrite thin film. They used phase-field modeling to simulate domains within a bismuth ferrite thin film and found that charged domain wall formation is energetically favorable because these additional charge-carrying particles shield the existing electric fields inside the thin film.

Based on the results of transient, small domains forming after a photodoping event, the team concluded that bismuth ferrite is an excellent candidate for fast manipulation of ferroelectric properties on timescales of sub-nanoseconds. Furthermore, they concluded that photodoping is superior to the more common chemical doping in this instance because it affects the material more quickly, the effects of photodoping are reversible, and the number of reversals possible without degradation is enormously high. – Mary Agner

____________________________________________________________________________________

See: B. Guzelturk1, T. Yang2,3, Y.-C. Liu4, C.-C. Wei4, G. Orenstein5, M. Trigo5, T. Zhou1, B. Diroll1, M. V. Holt1, H. Wen1, L.-Q. Chen2, J.-C. Yang4, A. M. Lindenberg5,6, “Sub-nanosecond reconfiguration of ferroelectric domains in bismuth ferrite” Adv. Mat. 35 44 2306029 (2023)

Author affiliations: 1Argonne National Laboratory; 2Pennsylvania State University; 3Shanghai Jiao Tong University; 4National Cheng Kung University; 5SLAC National Accelerator Laboratory; 6Stanford University

The authors thank Lane W. Martin for the initial discussions. Work performed at the Center for Nanoscale Materials and the Advanced Photon Source, both U.S. Department of Energy Office (DOE) of Science User Facilities, was supported by the U.S. DOE, Office of Basic Energy Sciences, under Contract No. DE-AC02-06CH11357. Extraordinary facility operations were supported in part by the DOE Office of Science through the National Virtual Biotechnology Laboratory, a consortium of DOE national laboratories focused on the response to COVID-19, with funding provided by the Coronavirus CARES Act. T.Y. and L.-Q. C. are supported as part of the Computational Materials Sciences Program funded by the U.S. Department of Energy, Office of Science, Basic Energy Sciences, under Award No. DE-SC-0020145. G.O. acknowledges support from the Koert Foundation. H.W. acknowledges the support for instrument development by the U.S. Department of Energy, Office of Science, Basic Energy Sciences, Materials Sciences and Engineering Division. H.W. acknowledges support for conceiving the initial experiments by the U.S. Department of Energy, Office of Science, Basic Energy Sciences, Materials Sciences and Engineering Division, under contract number (DE-SC-0012375). G.O., M.T., and A.M.L. acknowledge support from the Department of Energy, Office of Basic Energy Sciences, Division of Materials Sciences and Engineering, under contract number DE-AC02-76SF00515. J.-C.Y. acknowledges the financial support from the National Science and Technology Council (NSTC) in Taiwan under grant no. NSTC-112-2112-M-006-020-MY3.

The U.S. Department of Energy's APS at Argonne National Laboratory is one of the world’s most productive x-ray light source facilities. Each year, the APS provides high-brightness x-ray beams to a diverse community of more than 5,000 researchers in materials science, chemistry, condensed matter physics, the life and environmental sciences, and applied research. Researchers using the APS produce over 2,000 publications each year detailing impactful discoveries and solve more vital biological protein structures than users of any other x-ray light source research facility. APS x-rays are ideally suited for explorations of materials and biological structures; elemental distribution; chemical, magnetic, electronic states; and a wide range of technologically important engineering systems from batteries to fuel injector sprays, all of which are the foundations of our nation’s economic, technological, and physical well-being.

Argonne National Laboratory seeks solutions to pressing national problems in science and technology. The nation's first national laboratory, Argonne conducts leading-edge basic and applied scientific research in virtually every scientific discipline. Argonne researchers work closely with researchers from hundreds of companies, universities, and federal, state and municipal agencies to help them solve their specific problems, advance America's scientific leadership and prepare the nation for a better future. With employees from more than 60 nations, Argonne is managed by UChicago Argonne, LLC, for the U.S. DOE Office of Science.

The U.S. Department of Energy's Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, visit the Office of Science website.