1. Finding the Keys to Keyhole Formation in 3-D Printing

1. Finding the Keys to Keyhole Formation in 3-D Printing

Additive manufacturing (AM), more commonly known as three-dimensional (3-D) printing, is transforming the industrial world in myriad ways, making the journey from initial concept to finished design to physical reality much faster, cheaper, and more efficient. Various AM techniques have been developed, including laser powder bed fusion (LPBF), binder jetting, material extrusion, direct energy deposition, and others, each with their own characteristics and applicability to different materials, objects, and purposes. Yet our understanding of the basic dynamics and physical processes controlling these techniques remains incomplete and imprecise, leading to a lack of precision control during fabrication and the creation of defect-laden parts that may fail to meet desired standards. In some cases, models of AM processes are based on indirect measurements and visualizations and on analogies with other industrial techniques such as welding, not all of which are fully comparable to AM. Researchers from Carnegie Mellon University and Argonne National Laboratory have been working to change this situation through the development of ultrahigh-speed x-ray synchrotron imaging techniques at the U.S. Department of Energy’s (DOE’s) Advanced Photon Source (APS), an Office of Science user facility at Argonne. The APS Upgrade takes these techniques, and allows us to extend them toward significantly improved spatial resolution as well as improved contrast for low-visibility features, which allow us to study these systems in greater detail, and with much better sensitivity.

In their latest work, published in the journal Science,[1] they investigated the phenomenon of vapor depressions, known as “keyholes” in the laser melting of metals, commonly involved in the AM technique of LPBF. Working at the X-ray Science Division (XSD) beamline 32-ID-B at the APS, they found that contrary to the gradual transition from a “conduction mode” (a shallow, semicircular melt pool) to a “keyhole mode” (deep and narrow melt pool) as traditionally believed, there is a well-defined threshold for the transition, keyholes are present throughout the LPBF process, and they vary in a predictable manner.

The ability to directly visualize the evolution of the vapor depression dynamics through ultrafast x-ray imaging allowed the research team to precisely characterize the development of the melt pool and formation of the vapor depression, and the quantitative relationship between power density, drilling rate, and front wall angle of the keyhole, with both a stationary and moving laser beam.

Under a stationary x-ray beam, the research team observed five distinct regimes. After initial melting of the metal powder under the laser, a vapor depression formed and began to grow, followed by the formation of instabilities in the vapor depression. This led to formation of a keyhole and finally a marked change in the shape of the melt pool, from a semicircular shape to bimodal, with a bowl-shaped area on top and a deep spike on the bottom. More power translated into deeper penetration.

The main parameters for both laser welding and AM are laser power and velocity, defined as P-V space. In the scanning beam experiments, the research team found that unlike in the stationary beam measurements, vapor depression morphologies changed markedly in P-V space, with almost all combinations of power and velocity resulting in the formation of a substantial vapor depression. Measuring vapor depression depths as a function of laser velocity and power for spot sizes of 95 µs and 140 µm showed a very linear depth vs. power relationship for most beam-scanning velocities.

Although models to predict vapor depression dynamics are available, they tend to require large computational resources and are not easily scalable. The current experiment team adopted a less complex prediction model based on these experiments, which uses the unique capabilities of the ultrafast x-ray imaging method and the high brightness of APS x-rays. By calculating the front-wall angle of the keyhole as a function of beam velocity and power density, it is possible to estimate the keyhole depth. With some minor corrections, this model proved to fit the present data sets quite well. Further experiments using powder bed samples and different materials introduced some variations, but similar overall trends, with the relationship between front wall angle and keyhole depth shown to be unaffected by the type of material used.

These imaging studies and modeling of keyhole formation and morphology under laser heating in LPBF additive manufacturing are an important advance that will allow LPBF users to better predict the behavior of their equipment and avoid the problems of deep keyholing that result in porosity defects and instability in AM-made parts.

– Mark Wolverton

2. Penetrating the Depths of the Binder Printing Process

2. Penetrating the Depths of the Binder Printing Process

Binder jetting is one of the most versatile and powerful methods of 3-D printing. After a part is created, it can be used as a mold, sintered to make a final part, or combined with another material to create a composite object. Binder jetting can be performed with both metallic and ceramic materials, does not require support structures for the fabrication of parts, and has the added advantage of mitigating thermal stresses and microstructural defects because the printing and densification processes are performed separately.

But as with every other AM process, certain phenomena can affect the quality and durability of objects created through binder jetting. Variations in the characteristics of the powder and binder material used, the design of the individual part, and the choice of post-fabrication procedures can all introduce defects in the finished part. One obstacle is a limited understanding of the basic mechanisms that control the binder jetting process. Previous studies using visible light were unable to completely visualize the fundamental mechanisms, and also employed continuous-jetting inkjet print-heads rather than the droplet-on-demand (DoD) heads used in most commercial printers.

Now, the team of Argonne National Laboratory and Carnegie Mellon University researchers, with colleagues from The Barnes Group Advisors, utilized high-speed synchrotron x-ray imaging at the U.S. DOE’s Advanced Photon Source to open up a more revealing window into the processes of binder jetting AM. Their work was published in Scientific Reports.[2]

The research team adapted an experimental set-up they previously used to study other AM mechanisms at the XSD beamline 32-ID-B to investigate binder jetting with a variety of materials with high spatial and temporal resolution. Because the process begins with the generation and subsequent behavior of the binder droplets, the team first examined droplet geometry and dynamics in DoD-type print heads, which are more commonly used because of their high resolution and reliability.

Repeated experiments revealed that the droplet initially displayed a chiefly cylindrical head, which changed to spherical as it fell, followed by a long, thin tail. Three to five main satellite droplets were seen at the end of the tail, with some smaller droplets at the very end. The droplet velocity and separation were measured to be essentially consistent with the printer settings. As the droplet changed shape, a neck region formed between the head and tail, which can pinch off; although in the present experiments, the head was seen to impact the powder bed before this occurred. Satellite droplets fell more slowly than the head droplet, indicating that they were formed by the instability of the tail. No splashing of the binder was observed, but the horizontal movement of the print head resulted in drift of the satellite droplets. This drift can be expected to increase with greater print-head velocity, which may account for the decreased dimensional accuracy previously seen in binder jetting printed parts as print-head speed increases.

Unlike other imaging modalities, the high-speed, hard x-rays from the APS allowed visualization of the subsurface activity in the powder bed after the binder droplets fell. Upon droplet impact, the powder particles underneath were ejected from the bed. Defining the depth of disturbance as the “interaction depth,” the experimenters observed that the interaction depth depended on particle size and morphology, decreasing with larger particles and increasing with more irregularly-shaped particles. The particle substance also affected ejection behavior because of different flow-ability and mass characteristics. These phenomena are important factors in the possible formation of defects: Deep interaction depths can create subsurface pores, particle ejections can result in depletion zones and pores, and ejected particles can affect the formation of subsequent powder layers, causing roughness and dimensional inaccuracies. Smaller particle sizes also displayed significant agglomeration, with binder droplets coalescing to form larger spherical agglomerates that could disrupt spreading of subsequent layers and form defects.

These experiments provide a vital insight into the fundamental mechanisms at work in binder jetting. With this more complete and detailed knowledge now available, it will be possible to better tailor the fabrication of binder jetting-produced parts using various materials and conditions with fewer defects, and develop new binder-jetting printers with enhanced capabilities. – Mark Wolverton

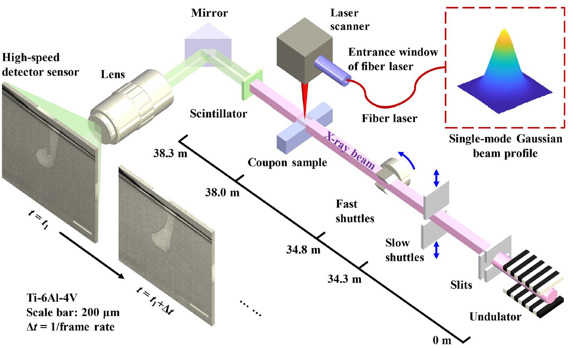

3. An Ultrafast Look Inside Laser Powder Bed Fusion

In the continually expanding realm of AM, laser bed powder fusion (LPBF) has become the most popular method for the fabrication of metal parts. In LPBF, a laser scans an extremely thin powder layer atop a substrate layer, creating a new metal layer by melting powder particles along with some of the substrate. Because the processes involved are highly dynamic, including high temperatures and rates of melting and cooling, LPBF is a complex technique involving powder ejection, melting and vaporization, molten metal flow and solidification, nonequilibrium phase transitions, and other various phenomena, all of which can have crucial implications for the quality and characteristics of the finished part and the presence or absence of structural defects. Thus, the ability to observe and study the LPBF process in situ is vitally important in order to achieve a better understanding and control of this 3-D printing technique. But because of the extremely localized and very fast nature of these phenomena, they are quite difficult to visualize adequately. Most previous attempts to do so have used high-speed visible light or thermal imaging techniques, but these are limited by their inability to image subsurface features and the behavior of scattered particles. The experimenters from Argonne, Carnegie Mellon University, the Missouri University of Science and Technology, and the DOE’s National Security Campus used ultrahigh-speed x-ray synchrotron imaging techniques at the Advanced Photon Source to observe the fundamental physical processes involved in the LPBF method. The work was published in the Journal of Synchrotron Radiation.[3]

Again utilizing the XSD 32-ID-B x-ray beamline, the research team used a custom experimental set-up they had previously employed to study other AM methods, adding an ultrafast imaging camera capable of extremely high temporal resolution and recording speeds, and also a laser scanner so that the actual LPBF process could be reproduced with a moving laser beam instead of the stationary beam of previous experiments. Powder bed samples of three different metallic alloys commonly used in LPBF manufacturing were studied: aluminum alloy (Al-10Si-Mg), titanium alloy (Ti-6Al-4V), and nickel alloy (Inconel 718). Both absorption and phase contrast x-ray images were obtained at various frame rates and exposure times to capture different phenomena at various time scales.

A variety of exposure times and speeds allowed the visualization of a wide range of phenomena. For example, denser samples such as the Inconel alloy required greater exposure times in order to image details of the melt pool formation, while the behavior of other materials could be adequately seen at lesser exposures. The multi-frame, high-speed camera was used to image the entire length of the laser scan with each sample, providing a full record and imaging of the important phenomena governing the LPBF process.

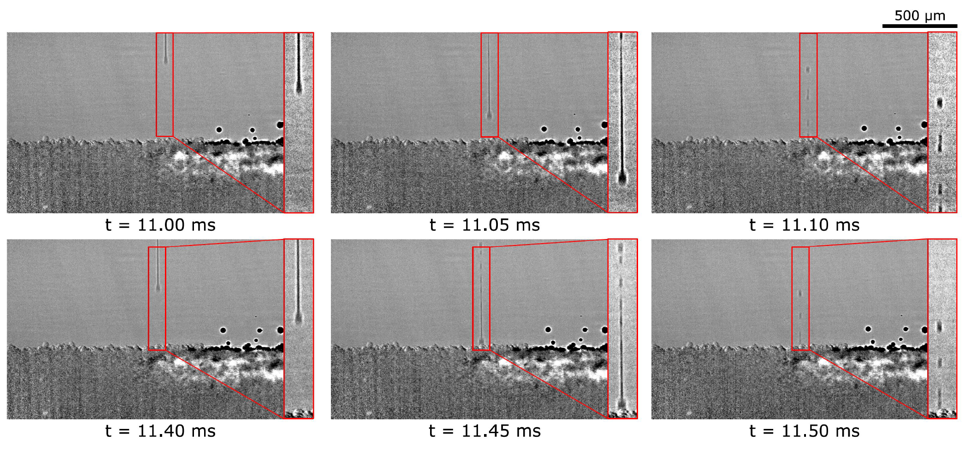

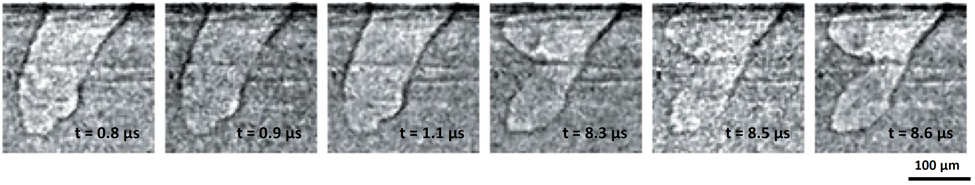

Ultrafast imaging was used at rates of 1.08 million and 10 million frames s-1 to examine some of the extremely fast and dynamic events that occur during LPBF fabrication. The latter speed is the fastest rate possible with currently available cameras. This allowed visualization of the formation of vapor depressions in the aluminum samples and changes in their sizes and shapes. Other experiments showed the behavior of particles ejected from the powder bed, including tracking of their velocities and trajectories with better accuracy than previously possible, even those with irregular shapes.

This work has produced a wealth of new information on the intricacies of the LPBF process, from the formation and dynamics of melt pools to the formation of porosity in materials, the behavior of vapor depressions, and the ejection of powder particles. The experiments also helped to identify phenomena that particularly lend themselves to study under ultrafast recording speeds, and quantified for the first time the oscillations of vapor depressions and high-velocity rotating particles.

Unlike previous imaging methods, which could only provide incomplete and less detailed data, this ultrahigh-speed synchrotron x-ray technique provides new insights into the basic processes at the heart of the LPBF method of additive manufacturing. Such knowledge will not only facilitate the development of better control of LPBF fabrication methods and the consequent creation of stronger and more robust parts with fewer defects, but also help to devise improved numerical models as LPBF and other AM techniques continue to expand in their versatility and popularity. – Mark Wolverton

[1] See: Ross Cunningham1, Cang Zhao2, Niranjan Parab2, Christopher Kantzos1, Joseph Pauza1, Kamel Fezzaa2, Tao Sun2, and Anthony D. Rollett1*, “Keyhole Threshold and Morphology in Laser Melting Revealed by Ultrahigh-Speed X-ray Imaging,” Science 363, 849 (22 February 2019). DOI: 10.1126/science.aav4687

Author affiliations: 1Carnegie Mellon University, 2Argonne National Laboratory

Correspondence: *[email protected]

The work was supported by the Department of Defense, Office of Economic Adjustment, under grant number ST1605-17-02, Michael Gilroy, CTO & Program Director. The work was also supported by Laboratory Directed Research and Development funding from Argonne National Laboratory, provided by the Director, Office of Science, of the U.S. Department of Energy (DOE) under Contract No. DE-AC02-06CH11357. This research used resources of the Advanced Photon Source, a U.S. DOE Office of Science User Facility operated for the DOE Office of Science by Argonne National Laboratory under Contract No. DE-AC02-06CH11357.

[2] See: Niranjan D. Parab1, John E. Barnes2*, Cang Zhao1, Ross W. Cunningham3, Kamel Fezzaa1, Anthony D. Rollett3**, and Tao Sun1***, “Real time observation of binder jetting printing process using high-speed X-ray imaging,” Sci. Rep. 9, 2499 (2019). DOI:10.1038/s41598-019-38862-7

Author affiliations: 1Argonne National Laboratory, 2The Barnes Group Advisors, 3Carnegie Mellon University

Correspondence: *[email protected], **[email protected], ***[email protected]

We thank Alex Deriy from the APS for technical and safety support for beamline experiments, and Sean Wang from Northwestern University for the assistance in data analysis. A.D.R. and R.W.C. are grateful for the support of the ADAPT Mountain West Manufacturing Network. This research used resources of the Advanced Photon Source, a U.S. Department of Energy (DOE) Office of Science User Facility operated for the DOE Office of Science by Argonne National Laboratory under Contract No. DE-AC02-06CH11357.

[3] See: Niranjan D. Parab1, Cang Zhao1, Ross Cunningham2, Luis I. Escano3, Kamel Fezzaa1, Wes Everhart4, Anthony D. Rollett2, Lianyi Chen3, and Tao Sun1*, “Ultrafast X-ray imaging of laser–metal additive manufacturing processes,” J. Synchrotron Rad. 25, 1467 (2018). DOI: 10.1107/S1600577518009554

Author affiliations: 1Argonne National Laboratory, 2Carnegie Mellon University, 3Missouri University of Science and Technology, 4Department of Energy’s Kansas City National Security Campus

Correspondence: *[email protected]

This work was financially supported by Laboratory Directed Research and Development funding from Argonne National Laboratory, provided by the Director, Office of Science, of the U.S. Department of Energy (DOE) under Contract No. DE-AC02-06CH11357. N.D. Parab, L.I. Escano, L. Chen, and T. Sun are grateful for the support of Honeywell Federal Manufacturing and Technologies. A.D. Rollett and R. Cunningham are grateful for support from the University of Utah under grant No. U000095690. L. Chen acknowledges funding from the University of Missouri Research Board. This research used resources of the Advanced Photon Source, a U.S. DOE Office of Science User Facility operated for the DOE Office of Science by Argonne National Laboratory under Contract No. DE-AC02-06CH11357.

Argonne National Laboratory seeks solutions to pressing national problems in science and technology. The nation's first national laboratory, Argonne conducts leading-edge basic and applied scientific research in virtually every scientific discipline. Argonne researchers work closely with researchers from hundreds of companies, universities, and federal, state and municipal agencies to help them solve their specific problems, advance America's scientific leadership and prepare the nation for a better future. With employees from more than 60 nations, Argonne is managed by UChicago Argonne, LLC for the U.S. Department of Energy's Office of Science.

The U.S. Department of Energy's Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, visit the Office of Science website.