Industrial catalysts are used to speed up the reactions used in petrochemical processing, and the manufacture of fine chemicals are often based on precious metals, such as platinum, palladium, and gold. Chemists would like to find cheaper alternatives. In recent years, their attention has turned to better designs of precious metals for atom-efficient reactions. New, inexpensive, and more efficient industrial catalysts for fuel processing and chemical manufacture could emerge from new studies, carried out at the U.S. Department of Energy’s Advanced Photon Source (APS), into the different ways in which the active metal sites in a catalyst can be prepared when the catalyst metal is on an active or an inert support material.

Among these support materials are active oxide supports that include ceria (cerium dioxide), iron oxide, and titania (titanium dioxide); these substances all have their own inherent catalytic activity.

There are also "inert" oxide supports including the zeolites, alumina (aluminum oxide), and silica (silicon dioxide), which provide a large surface area in a small volume on which catalysis can take place but are otherwise inactive materials in the catalytic sense.

Chemists and chemical engineers have had success in catalyzing an important reaction known as the “low-temperature water-gas shift (WGS)” reaction with metal catalysts on the active oxide supports. This reaction converts carbon monoxide and water into hydrogen (for fuel and further processing), and carbon dioxide as a waste product. Moreover, they have recently identified how gold or platinum atoms are bonded and stabilized to the oxygen species in an active support. They have also found that they can boost the number of such active sites or create them on inert supports, even when none exist, by preparing and stabilizing the metal atoms with a number of charged sodium cations bound to the metal center through oxygen bonds.

These novel structures, which have been found to work well for both gold- and platinum-atom-centered catalysts, overcome the difficulty of preparing the conventional-type catalysts used in the water-gas shift reaction on inert supports. The single-metal cation (stable at the working temperatures of more than 120° Celsius) can be prepared readily in this alkali-modified form. A novel method for preparing Pt-Ox-Na-supported catalysts on porous minerals known as zeolites and on silica with medium-sized pores, mesoporous silica, involves the addition of sodium hydroxide in the solid state to the support already impregnated with a solution of a compound containing platinum. An effective and stable catalyst is then formed by heat treatment in air of this precursor.

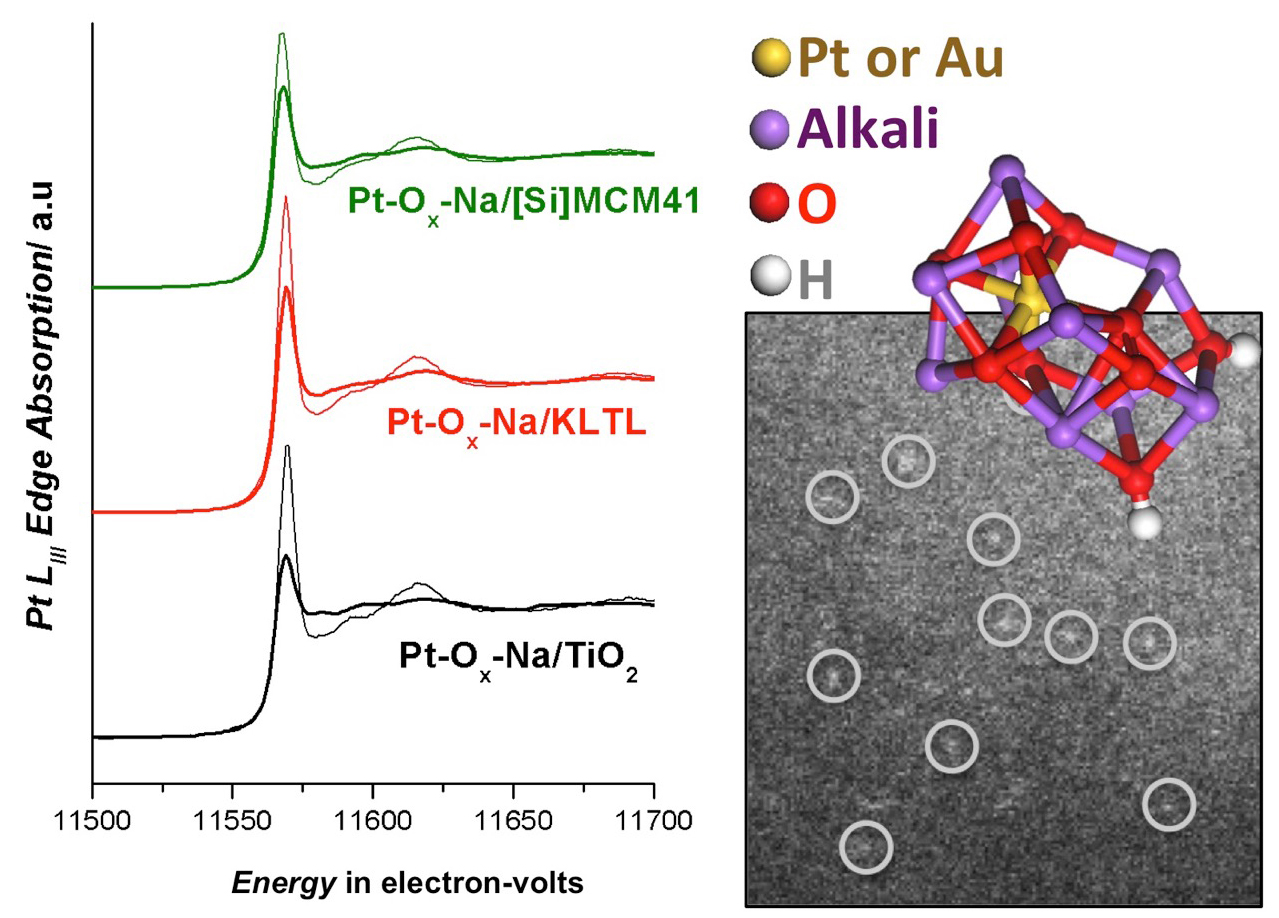

The researchers in this study from Tufts University, Argonne, the University of Sydney (Australia), and Oak Ridge National Laboratory carried out in situ x-ray absorption spectroscopy (XAS) experiments at X-ray Science Division x-ray beamline 12-BM-B at the APS, which is an Office of Science user facility. Their experiment spanned a range of temperatures from room temperature to 275° Celsius and demonstrated catalyst stability (Fig. 1).

Similar intrinsic (per platinum atom) activities were observed for three different sodium-containing platinum catalyst samples: The catalysts worked to accelerate the WGS reaction under realistic conditions from about 120° to 400° Celsius and their intrinsic activity did not depend on the choice of support.

The promise of these positive findings is that considerable platinum savings can be realized by preparing platinum at the atom limit on any support. To ensure atom stability on inert supports, the new method surrounds them with sodium or other alkali ions through oxygen bonds. In these new catalysts, inexpensive sodium is coupled with inexpensive support materials such as silica, which is extracted from sand, or zeolite minerals, which are extracted from clays. These are Earth-abundant materials found the world over in large quantities and so can keep the total catalyst cost low. For an active support such as ceria or titania, the new method can add catalytic Pt-Ox-Na sites above and beyond the capacity of the active support, thus increasing the total metal loading and also the total catalyst activity, while preserving the platinum at the active single atom (cation) Pt-Ox state. — David Bradley

See: Ming Yang1, Jilei Liu1, Sungsik Lee2, Branko Zugic1, Jun Huang3, Lawrence F. Allard4, and Maria Flytzani-Stephanopoulos1*, “A Common Single-Site Pt(II)−O(OH)x− Species Stabilized by Sodium on ‘Active’ and ‘Inert’s Supports Catalyzes the Water-Gas Shift Reaction,” J. Am. Chem. Soc. 137, 3470 (2015). DOI: 10.1021/ja513292k

Author affiliations: 1Tufts University, 2Argonne National Laboratory, 3University of Sydney, 4Oak Ridge National Laboratory

Correspondence: *[email protected]

Financial support by the U.S. Department of Energy-Basic Energy Sciences under Grant DE-FG02-05ER15730 is gratefully acknowledged. This research used resources of the Advanced Photon Source, a U.S. Department of Energy Office of Science User Facility operated for the U.S. Department of Energy Office of Science by Argonne National Laboratory under Contract No. DE-AC02-06CH11357.

Argonne National Laboratory is supported by the Office of Science of the U.S. Department of Energy. The Office of Science is the single largest supporter of basic research in the physical sciences in the United States, and is working to address some of the most pressing challenges of our time. For more information, please visit science.energy.gov.